- Paving

- Electrical Engineering and Telecoms Infrastructure

- Civil Engineering, Mining, Railway, Building and Plumbing Products

- Curbs / Kerbs

- Landscaping, Streetscaping, Gardening products

- Moulds

- Pizza Oven Kit

- Avalon range

- Builders' and Plumbers' Products

- Benches and Seats

- Concrete Tables

- Grass Blocks

- Litter/Refuse Bins

- Pots and planters (Discontinued)

- Tree rings

- Bollards and Barriers

- Stone Cellar Blocks

- Water features (Discontinued)

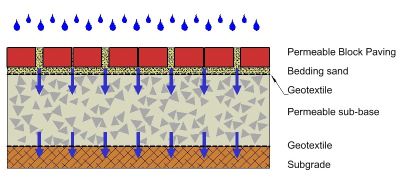

Key requirements for properly functioning permeable paving

The following are five KEY elements essetial for successful permeable paving:

1. Permeability of paving surface

The first and most important element is a hard paved surface that is adequately permeable. This allows water to infiltrate the paving instead of collecting on it and running over it. Conventional paving does not pertmit infiltration. Permeable paving blocks must be specially designed with the intent to the purpose. Such blocks have special openings and regulated wider spaced joints to achieve the necessary voids. The permeability of Precast Concrete Block Paving is expressed as a void persentage i.e. the ratio of the sum of void areas to the total area of the paving.

The larger the void percentage, the better the expected infiltration. In the USA, published research and experience* reports acceptable functioning with a void percentage of at least 9%. Paving areas that were surveyed with larger percentages of up to 15% proved to have excellent infiltration. Vanstone's blocks have void percentages of 14% for Aqualock and 12.7% for Aqua Random.

Please note, there is a limit to void persentage. See Strength of Paving below.

2. Suitable filling and bedding sand

The voids provided in the PCBP as above must be filled with suitable open-graded sand. Normal filling sand (fine grained plaster or building sands) compacts densely and will block up the paving permanently.

Equally so, the bedding sand underneath the paving blocks must be porous enough to let the water through. Leaving this to chance may spoil an otherwise well functioning system.

The ideal sand for both filling and bedding is a fines-free sand with particles sizes between 2mm and 5mm. If it cannot be obtained exactly so, it is best to avoid sands containing particles larger than 5.5mm and/or smaller than 1mm. A washed and screened sand, whether crushersand or natural sand will work well. This applies generally to all PCBP including Vanstone's products.

3. Suitable road foundation

Road foundations (also called base courses or substrata) for permeable paving must be able to absorb the water received from the overlaying paving. For this to be possible, ordinary compacted gravel or crusherrun layers will not do the trick. Use a single graded crushed stone such as 13mm or 19mm. In case of multiple layers, the lower layer may consist of larger stones like 25mm or 38mm if it is more economical. Use a geofabric layer between the upper crushed stone layer and the bedding sand to avoid intermixing. Also use geofabric between the bottom of the crushed stone and the natural ground base if intermixing from the bottom-up is possible and may cause clogging.

Although these measures sound expensive, it must be remembered that well designed permeable paving will replace a conventional stormwater system. Such a system is costly with huge pipes, manholes, inlets, outlet structures and connections. Further, conventional stormwater systems require constant maintenence or become derelict. This is not the case with stormwater management based on permeable paving.

4. After-management of stormwater

Once the permeable paving system as described above has collected the rainwater efficiently, this water still has to be managed. If the natural ground is sufficiently absorbent like sandy soil, no further management is necessary. Semi-absorbent soils will require some drainage pipes to release excess water while dense soils like clay will need more or larger pipes. See the Engineer's Introduction for more complete information on stormwater management.

When needed, the drainage pipes should be no more than small diameter (50mm - 100mm) economical class pipes. PVC, HDPE or such are suitable as long as they are installed correctly.

Opposed to this, conventional stormwater systems need large diameter pipes. Two reasons (not applicable to permeable paving) makes this essential: 1. Large pipes are needed to handle high intensity rain storms of short duration but they stand empty most of the time; 2. Because all kinds of matter are able to enter the pipes, they are always subject to clogging. Small diameter stormwater pipes simply cannot be de-clogged and sizes smaller than 300mm is simply not practical. Permeable paving allows water to migrate over a large area into the porous road foundation. Here the flood is attenuated or kept on hold. Small diameter pipes (if required) now have time to drain the excess water away. With permeable paving no foreign matter is able to enter the underground for obvious reasons. The water found in the road foundation is already filtered and the small diameter pipes are at no risk of clogging.

5. Strength of paving

Naturally the strength of the paving or its ability to carry the traffic for which it is meant, must never be compromised. Over-emphasis on permeability may do just that as too many voids and joints that are too wide means less efficient interlock between blocks. Since block paving rely on this action to achieve its loadbearing capacity, a too large void percentage would severely compromise the paving. Blocks will act individually: move about, sag and become dislodged.

Obviously interlocking is not only dependent on void percentage but the shape of the blocks is equally important. As an example standard interlocking paving (type SA) has been in use as dry paving with great success for decades. The better the shape of the block, the better the interlock. For permeable paving, the better the shape of the block, the more voids can be allowed without compromising interlock.

Vanstone's Aqualock pavers reach a perfect compromise: Excellent interlock with a high percentage of voids. It is suitable for road traffic.

Vanstone's Aqua Random is meant for pedestrian paving and do not need the same strength of interlock. It is aesthetically pleasing and versatile.

* Bruce K. Ferguson: Porous Pavements, CRC Press 2005